Best Practices for B2B Last-Mile Delivery Operations in 2026

January 15, 2026

Until now, last-mile delivery had always been the last priority, something that people would worry about only when everything else was sorted. But now in 2026, it’s the first thing in the world of supply chain management. Customers notice it, they remember it. Mess up the final mile delivery, and you don’t just lose a delivery, you lose their trust, and sometimes the customer for good.

This is especially true for FMCG distributors, wholesale delivery services, D2C brands with a wide reach, and anyone who relies on field sales. Growth rises or falls on that final leg. Market research shows last-mile delivery eats up almost 53% of the total shipping costs. It’s not just about money either; this is where customers form their final impression of a brand.

A fast delivery is great, but that’s not enough anymore. People now expect reliability and transparency across the entire last mile delivery process. The businesses leading the pack in 2026 get this. They’re not just chasing the latest tech but they’re nailing the basics of last-mile delivery strategy, too.

1. Creating Sustainable Delivery Networks that Cut Costs

Let’s talk about building sustainable delivery networks that actually save money. Lots of companies race to promote electric vehicles into their fleets, but they miss the point if they don’t fix transportation planning first. Sure, an electric van cuts emissions, but if it’s taking wasteful routes or hauling half-empty loads, you’re just compounding old issues.

By 2026, sustainable delivery means more than checking a regulatory box or boosting your brand. Electric-powered delivery trucks are now proving their cost-effective benefits on urban and semi-urban routes, with advantages including stable fuel prices, reduced maintenance requirements, and simpler routes to restricted zones within cities.

When you use battery-electric vehicles on predictable city routes, they can go toe-to-toe with diesel vehicles in terms of total costs, sometimes they even come out ahead. That’s not just wishful thinking; the ICCT report backs it up. Electric trucks used for delivering goods reach cost parity or sometimes even lower lifetime costs compared to diesel trucks, when daily mileage and route energy needs are well matched. McKinsey says light delivery vehicles are the best candidates for electrification, thanks to their repeatable routes and shorter distances.

For mid-sized distributors, the strongest results come from converting the right routes, and not the entire fleet. Routes that run under 200 kilometers a day and include many closely spaced delivery stops tend to deliver the fastest returns. Such routes typically handle most daily deliveries and only rely on overnight charging, requiring no major infrastructure upgrades.

Now here it’s all about the sequence of things. Teams that begin by grouping nearby stops, cutting out empty miles, and filling existing trucks smarter before bringing in electric vehicles see bigger and faster savings. Train drivers, keep tweaking the routes, and you’ll stretch range and save even more. The real savings start to show only after you fix the routing headaches.

2. AI Route Optimization: Smart Thinking or Just Faster Tools?

Here’s what teams usually fail to understand: Brands pour money into route-optimization tools that promise to cut down on the drive time and distance, but most of these systems ignore the common local quirks like regional habits, changing seasons, or their cultural details. So dispatchers end up fixing what was supposed to be a “perfect” routing, often on the fly.

Everyone’s racing to adopt route-optimization tools, but honestly, the quality is all over the place. Grand View Research says that the global route optimization market was valued at USD 8.51 billion in 2023 and is projected to grow to USD 21.46 billion by 2030, at a CAGR of 14.4% from 2024 to 2030.

What’s making the real difference then? Static versus adaptive intelligence. Static systems just plot a route once and call it a day. Adaptive ones keep learning, tweaking routes in real-time based on traffic, weather, local regulations, delivery quirks, and even customer schedules.

As last-mile operations grow more complex, companies are now considering route optimization to reduce fuel waste, improve delivery reliability, and bring consistency to daily dispatch decisions especially in dense and multi-stop delivery regions. The trick here is all about learning. The best systems capture local rules, be it seasonal rushes, cultural habits or any unusual laws alongside keeping a strong core algorithm that works just about everywhere. By 2026, routing won’t just be about planning ahead. It’ll be more about making decisions on the fly, in real time, to solve the last mile problem effectively.

3. Small Fulfillment Centers: More Speed, No Loss in Focus

Teams often struggle with small fulfillment centers, not because automation costs too much, but because they add too many products too soon. That overload makes it a nightmare to track inventory and slows everything down, which eats into profits.

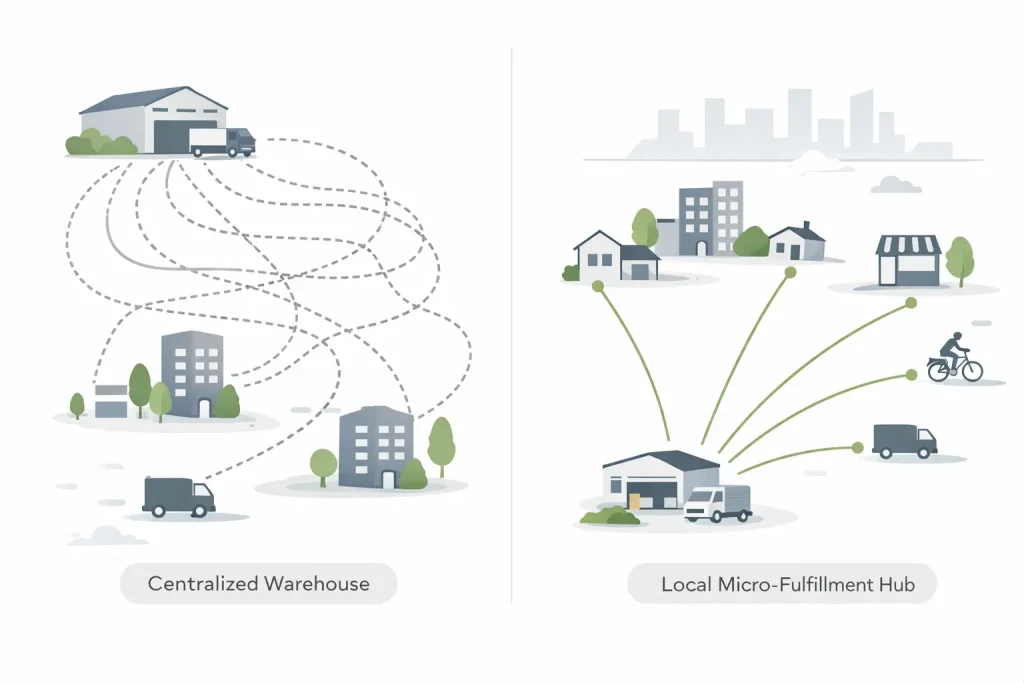

Micro-fulfillment centers (MFCs) cut delivery costs by moving inventory closer to customers, shortening delivery distances and improving speed. There have been several instances across the market, with report publishers pointing to the speedy growth rate associated with micro-fulfillment.

The smart move isn’t chasing automation just because it’s trendy. It’s about stocking the fastest-moving 20% of products, the ones that actually drive most sales. That way, businesses speed up fulfillment without drowning in inventory.

Well-placed micro-fulfillment centers can make a real difference in the last-mile distribution by consolidating inventory closer to demand and reducing unnecessary travel.

Evidence from simulations of urban consolidation centers – a very similar hub-based delivery model – suggests that truck kilometres driven could be reduced by about 65%, with emissions reduced by approximately 70% when deliveries are routed through well-designed local hubs.

Execution economics also matters a lot. In high-wage regions, automation tends to yield quicker returns, while in more cost-sensitive markets, hybrid models blending automation with manual picking often perform better.

4. Adaptable Delivery Choices to Match Customer Expectations

Adding more and more delivery options doesn’t always make your customers happier. Too many choices tend to confuse people, and leads to cart abandonment. Baymard Institute research indicates that 18% of shoppers abandon checkout because it feels too lengthy or too complex. This fact again confirms that clarity is more important than quantity where delivery options are concerned.

Deliveries also vary by market. In competitive retail markets, such as the United States, price sensitivity may play a bigger part in determining how a delivery gets made. In other areas, it may come down to reliability, assurance of delivery, or even sustainability based on local conditions.

The best teams tailor shipping options to what customers actually want, not just what’s fastest. They use data on past behavior, location, and cultural preferences to cut down on decision fatigue and boost sales. In 2026, real flexibility will mean smart planning and not endless lists of choices. This includes offering a mix of next-day delivery, same-day delivery, and even free shipping options to cater to various customer needs.

5. Smarter Tracking Systems to Build Trust

Most teams treat package tracking as an afterthought-something that starts well after checkout. In reality, tracking plays a central role in building trust, encouraging repeat purchases, and reducing support load.

Transparency is no longer optional. Many customers actively track their shipments, and bad communication consistently tops the list of common causes for delivery frustration. When updates are late, unclear, or inconsistent, confidence drops quickly.

This builds a trust challenge. While customers expect timely and personalized delivery updates, they are also wary of how their data is used. According to research from Pew Research Center, 79% of consumers are concerned about how companies treat personal data, which raises the bar for transparency in delivery communication.

The best tracking systems also deal head-on with the issue by tying route information, driver updates, and customer touchpoints into one coherent and reliable feedback loop. When customers know what is going on and why – support queries drop, including repetitive “Where’s my order?” calls. Ultimately, success isn’t just about accuracy; it’s about communicating clearly, consistently, and through channels customers trust.

Measuring What Really Matters in 2026

Most teams still obsess over cost-per-delivery, but honestly, that’s not the full picture anymore. What counts is how well your delivery experience keeps customers coming back and how much they’re really worth to you over time.

These days, smart e-commerce companies look at both the nuts and bolts of operations and the customer’s actual experience. They track how many deliveries show up on time and how often the first delivery attempt works out. They connect abandoned carts to the delivery choices customers see, then break down lifetime value based on how good those delivery experiences are.

Here’s the thing: The most useful insights come from tying performance back to specific customer groups, not just broad regional stats.

A Straightforward Way to Make Decisions in 2026

Strong teams don’t gamble on vague ideas. They zero in on what matters in last-mile delivery strategy:

- Pulling in £10–50M in revenue? Nail down route optimization and delivery tracking first. Only think about scaling your fleet or opening new fulfillment centers after you’ve got that sorted.

- Operating in more than one region? Make your routing flexible, but get local routing running smoothly before dropping money on micro-fulfillment.

- Margins looking tight? Drop those ultra-fast shipping guarantees. Instead, focus on smarter routes, better inventory management, and making sure you nail first-attempt deliveries.

- Losing customers? Double-check your update notifications and make your customer communication stronger before trying to speed things up even more.

Conclusion

In 2026, last-mile delivery teams which would give more emphasis on accuracy rather than volume, will rise to the challenge. This shifting landscape in delivery will not see successful businesses merely react-but lead. This will be achieved with well-planned route optimization, integrating technologies of autonomous vehicles and delivery robots, and most importantly, honing in on what customers want. In this way, companies will be able to meet the hurdles on the final leg of delivery and prosper in the competitive arenas of e-commerce and logistics.

Written By

Product Marketing Manager

Prachi is a Digital Marketing Strategist with over 8 years of experience specializing in B2B content strategy, lead generation, and driving organic growth. With a strong background in optimizing digital channels, she brings a keen understanding of how technology-driven solutions, like those offered by RouteMagic, can transform operational efficiency and enhance customer satisfaction.